Katalogauszüge

Dimensions/Working Ranges Electrical Bucket Capabilities 76-116 m3 100-152yd3 IGBT-AFE Inverter Cabinets 4 or 5 Water-Cooled Boom Lengths 109.7-132.5 m 360-435 ft Hoist Motors 6to 8x 1230 kW 6 to 8 x 1,650 hp Rated Suspended Load 226,800-344,736 kg 500,000-760,000 lb Drag Motors 6to 8x 1230 kW 6to 8 x 1,650 hp Approximate Working Weight 5.8-7.5 million kg 13.1-15.9 million lb Swing Motors 7to 10x 932 kW 7 to 10 x 1,250 hp

Katalog auf Seite 1 öffnen

Offering the highest levels of overburden removal productivity at the lowest total cost per tonne (ton), the 8750 is the flagship model of the Cat dragline product line. The first dragline of any kind to be successfully equipped with AC IGBT drive systems, we developed this superior technology for the sole purpose of making your workday more productive, predictable, and most importantly, safe. 3

Katalog auf Seite 3 öffnen

AC Electrics More reliable and efficient electrics Tried and True AC IGBT Electric Drive System, Now on Mining Equipment’s Largest Platform You will experience greater machine uptime, lower operating costs, and faster cycle times with our AC dragline designs that leverage institutional knowledge built on 30 years of experience commissioning more than 200 AC equipped machines worldwide. Benefits over DC Machines • Superior availability – Routinely demonstrated electrical availabilities of greater than 95%. – Extended mean time between failures, and reduced mean time to repair. • Better...

Katalog auf Seite 4 öffnen

AC Technology Optimizing your AC system performance and reliability, we’ve incorporated the latest in AC technology and utilized the most durable components available. Motion Regulator Control (MRC) • Sturdy, mine-grade cabinet mounted on a self supporting steel structure encloses all power and control electronics. • AFE, rather than rectifiers, convert AC to DC power. • Fuseless IGBT modules in AFEs and inverter. • Onboard maintenance computer is easy to troubleshoot, quickly identifies faults, and provides instructions to resolve issues. • Major control and power electrics are derived...

Katalog auf Seite 5 öffnen

Operator’s Cab Maximize your performance with enhanced safety and comfort features 6

Katalog auf Seite 6 öffnen

Comfort Infused, State-of-the-art Operator’s Cab and Station Providing more comfort, added safety, and greater reliability, our newly designed state-of-the-art operator’s cab will help you produce more. The product of a multi-year collaboration with mining companies from across the globe, our Design Engineers, armed with insights into the aspects most desired by you, have designed what we believe to be the most comfortable and productivity-enhancing operator’s cab in the industry. • Improved operator performance – Reduced cognitive fatigue and enhanced productivity via the intuitive...

Katalog auf Seite 7 öffnen

Mechanical Systems Maximizing your uptime with durable and dependable mechanical systems 8

Katalog auf Seite 8 öffnen

Keeping You Up and Running with Meticulously Engineered and Globally Proven Mechanical Systems Reliability you’ve come to depend on, our dragline mechanical systems have proven field history in mine sites across the globe, from the extreme heat of Australia to the frigid temperatures of Canada. Swing Machinery • Highly reliable swing planetary transmission and output pinion. • Interchangeable parts across all swing drives. • Potential for machine to operate with removal of one swing unit (typical maintenance). • Cooler/filtration unit plumbed to each planetary gearcase. Controlled and...

Katalog auf Seite 9 öffnen

Major Structures Bolstering your life-of-mine investment with robust and durable dragline structures Rugged Structures Designed and Fabricated to Withstand Your Extreme Mining Conditions To extend service life and ultimately reduce your maintenance cost, all major dragline structures are designed for durability and dependability. Extended performance in the harsh mining conditions you face daily is accomplished through selection of high-strength steels, and rugged castings, joined and thermally stress-relieved to create a reliable shell capable of the most productive surface extraction...

Katalog auf Seite 10 öffnen

Revolving Frame Assembly Boom Assembly • Deep, rectangular frame structure, running full length of assembly. • Integrated thick rail pad circumferential diaphragm sub-weldment, UT tested, and ground. • Thick integrated plates for support of main machinery. • Penetrations reinforced with through thickness plates as determined per FEA. • Rectangular, deep cross section geometry, constructed of high strength wide flange beams. • Pre-stretched galvanized main support ropes with equalizers. Kevlar intermediate boom support ropes . • Drop down stabilizer rope to mitigate dynamics in main support...

Katalog auf Seite 11 öffnen

Cat® MineStar™ System and Technology Solutions Evolving your mine for greater safety and productivity Helping You Enhance Safety and Productivity through Technology Aimed at enhancing the productivity and profitability of your dragline, we currently offer a combination of Cat MineStar System offerings and Cat dragline technology solutions. Cat MineStar System Helping you achieve your goals for enhanced mine site safety, improved efficiency, reduced operating costs, and greater profitability, the Cat MineStar System provides the most comprehensive suite of mining technology products in the...

Katalog auf Seite 12 öffnen

The Cat 8750 dragline is currently able to utilize two of the Cat MineStar System capability sets: • Fleet – Fleet provides real-time machine tracking, assignment and productivity management, providing a comprehensive overview of all your asset operations from anywhere in the world. • Terrain – Terrain enables high-precision management of drilling, dragline, grading and loading operations through the use of guidance technology. It increases machine productivity and provides you real-time feedback for improved efficiency. The remaining Cat MineStar System capability sets are currently under...

Katalog auf Seite 13 öffnen

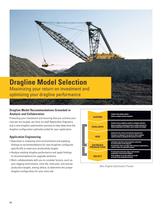

Dragline Model Selection Maximizing your return on investment and optimizing your dragline performance Dragline Model Recommendations Grounded in Analysis and Collaboration Protecting your investment and ensuring that you achieve your cost per ton targets, we have on-staff Application Engineers and a new dragline optimization process to help determine the dragline configuration optimally suited for your application. Application Engineering • Specialize in analyzing mine environments and applying findings to recommendations for new draglines configured specifically to meet your productivity...

Katalog auf Seite 14 öffnenAlle Kataloge und technischen Broschüren von Caterpillar Global Mining

-

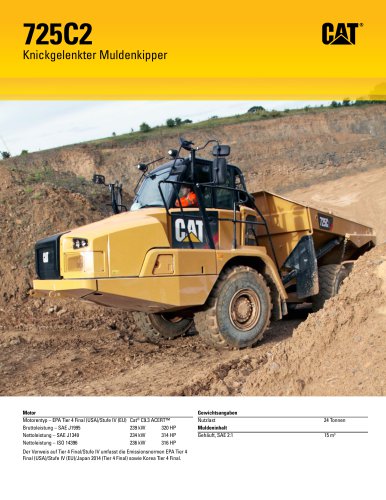

725C2

28 Seiten

-

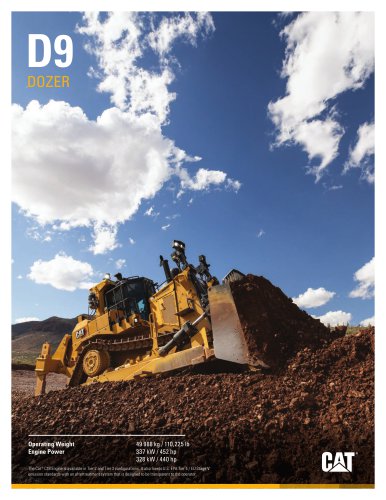

D9 DOZER

20 Seiten

-

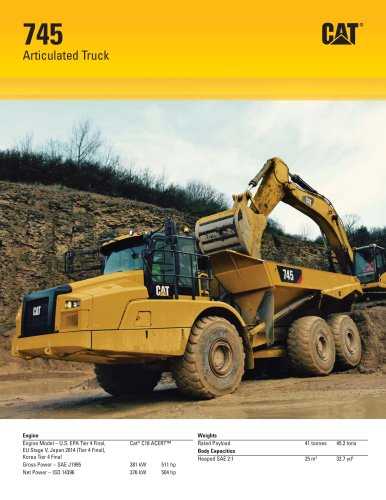

745

28 Seiten

-

Cat ® 621K

4 Seiten

-

D9T

20 Seiten

-

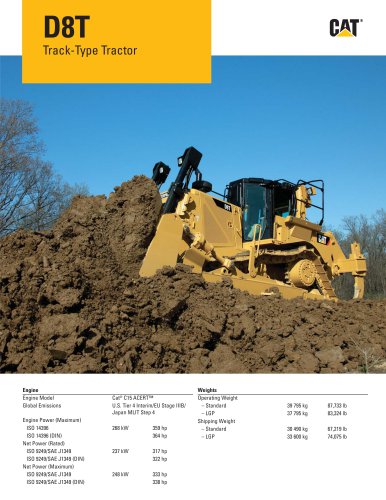

D8T

20 Seiten

-

735B Articulated Truck

20 Seiten

-

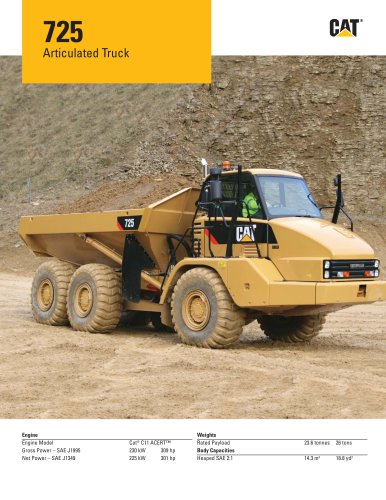

725 Articulated Truck

20 Seiten

-

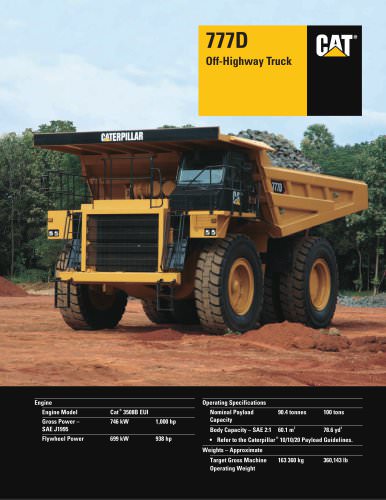

777D

28 Seiten

-

775G

32 Seiten

-

773E

24 Seiten

-

772G

28 Seiten

-

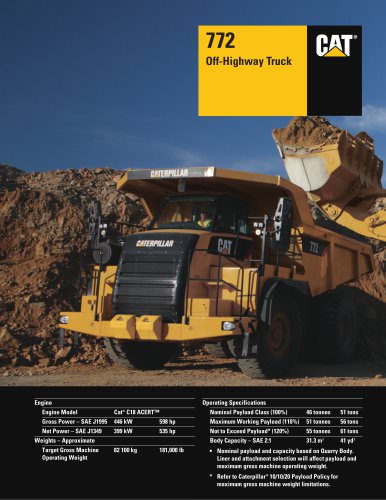

772

32 Seiten

-

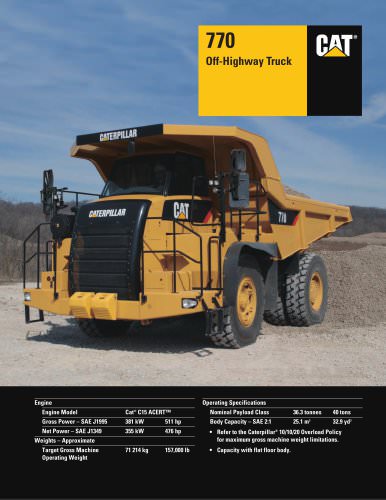

770

32 Seiten

-

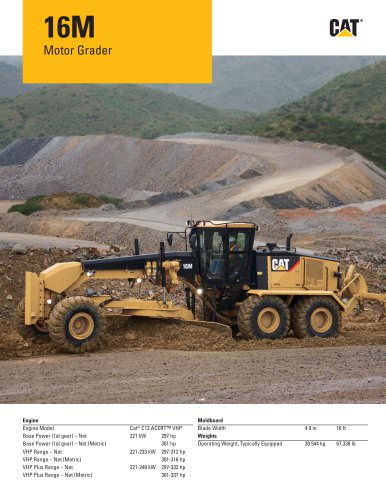

16M

24 Seiten

-

14M

28 Seiten

-

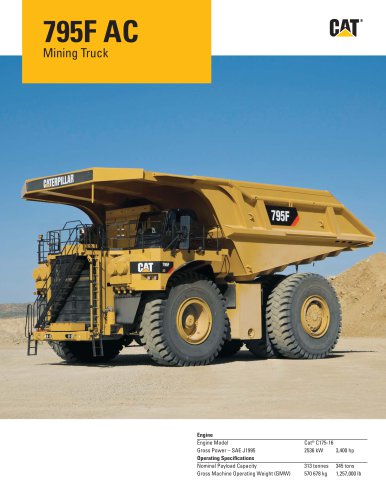

795F AC

24 Seiten

-

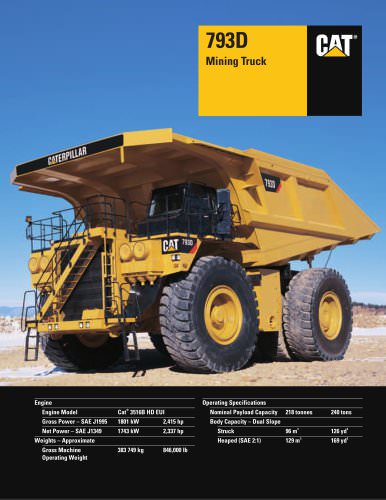

793D

32 Seiten

-

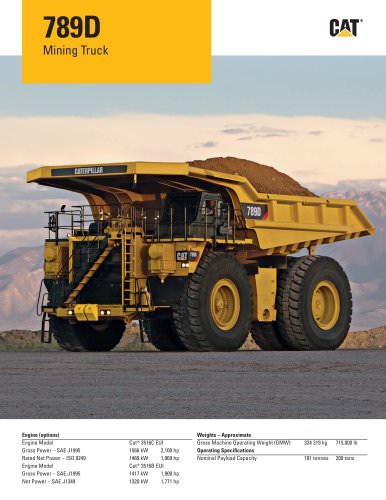

789D

28 Seiten

-

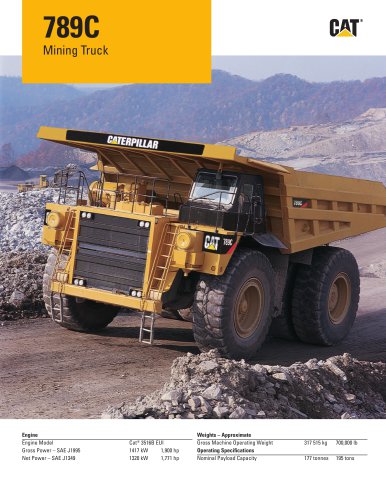

789C

28 Seiten

-

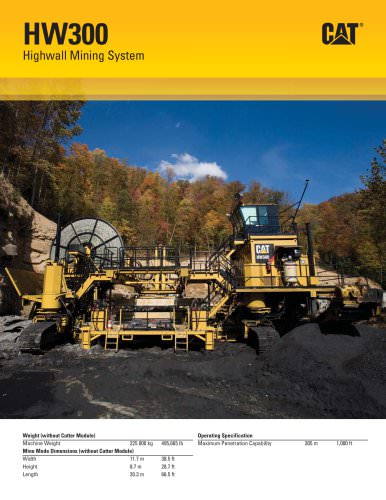

HW300

16 Seiten

-

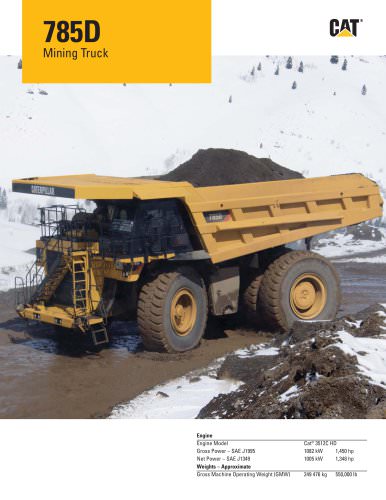

785D

24 Seiten

-

AEXQ1170 ShovelsBrochure

32 Seiten

-

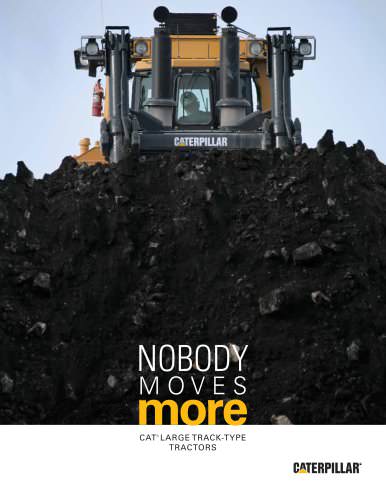

D11T/D11T CD

28 Seiten

-

D10T

20 Seiten

-

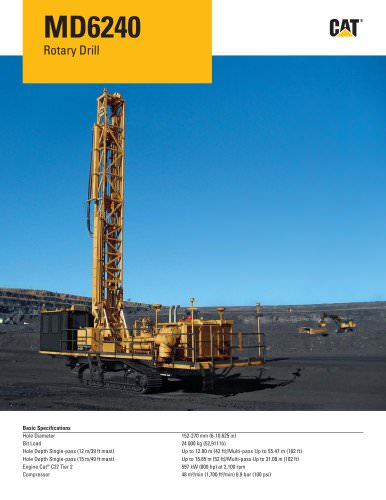

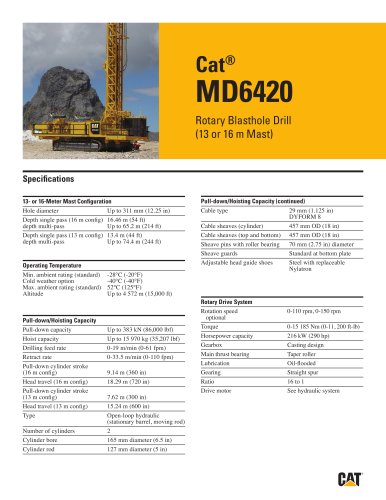

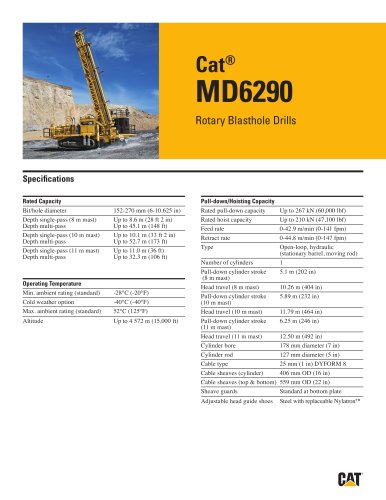

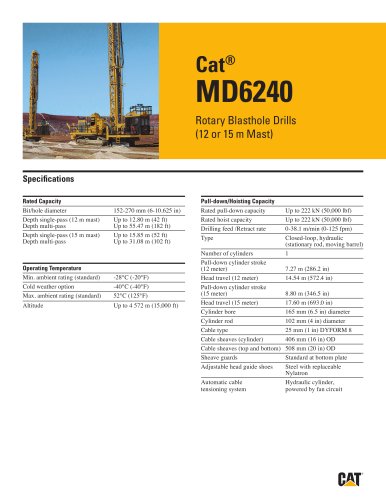

MD6240 Rotary Drill

28 Seiten

-

Cat ® Rock Flow System

2 Seiten

-

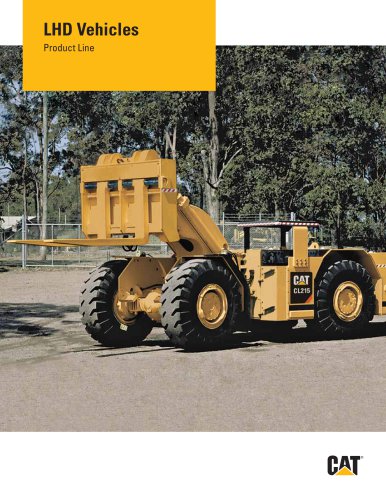

LHD Vehicles Product Line

8 Seiten

-

Mining Truck (797F)

28 Seiten

-

Motor Grader (16M)

24 Seiten

-

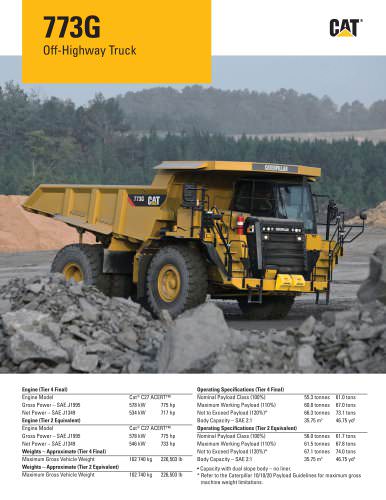

Off-Highway Truck (773G)

32 Seiten

-

Off-Highway Truck (777G)

36 Seiten

-

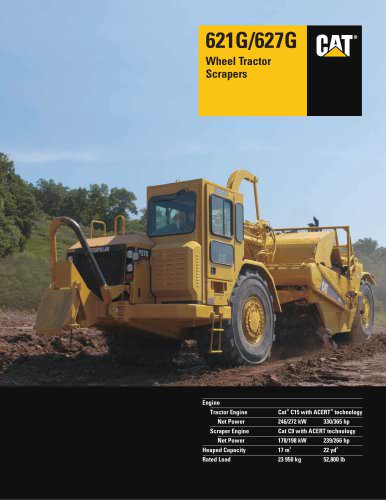

Open Bowl Scraper (627G)

24 Seiten

-

Open Bowl Scraper (627H)

20 Seiten

-

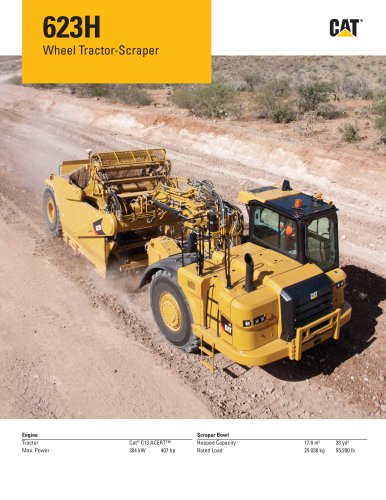

Open Bowl Scraper (623H)

20 Seiten

-

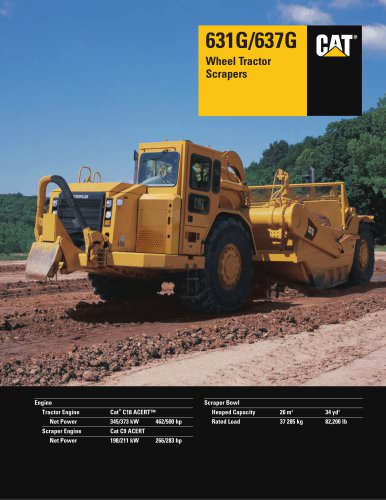

Open Bowl Scraper (631G)

24 Seiten

-

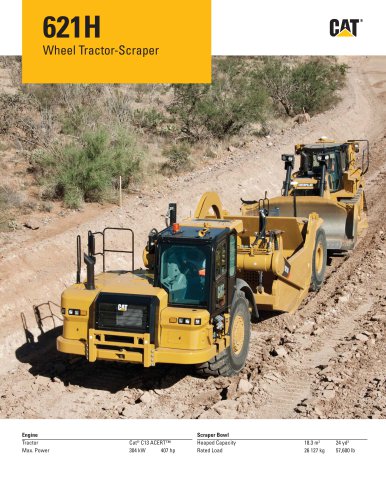

Open Bowl Scraper (621H)

20 Seiten

-

Open Bowl Scraper (657G)

24 Seiten

-

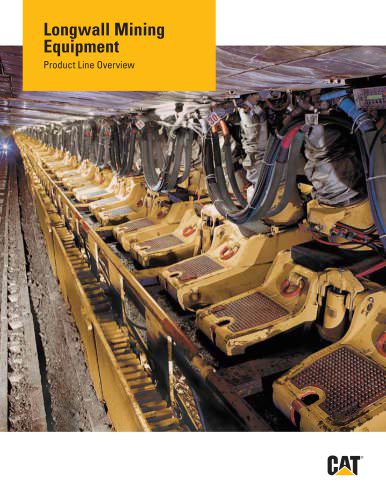

Longwall Mining Equipment

12 Seiten

-

LHD Vehicles

8 Seiten

-

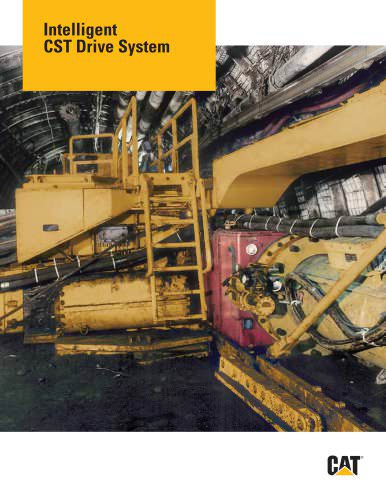

CTS Drive Systems

8 Seiten

-

Cat® Trucks: The ONE for Mining

28 Seiten

-

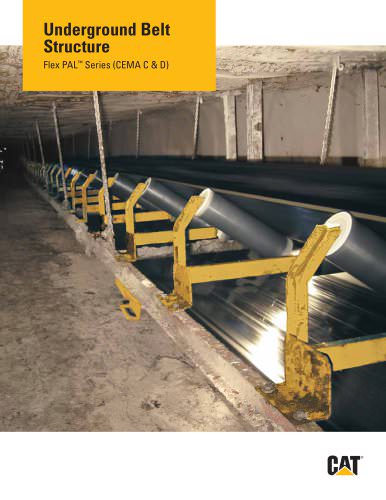

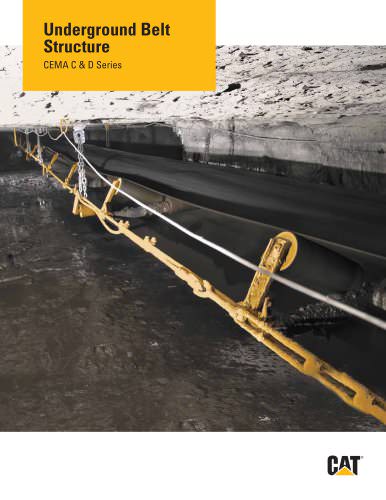

Belt Systems - Underground

12 Seiten

-

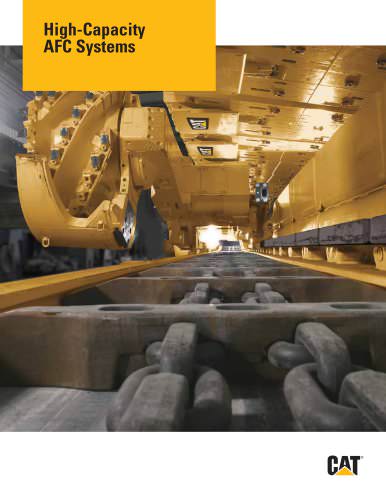

Armored Face Conveyors (AFCs)

12 Seiten

-

Longwall Automation

12 Seiten

-

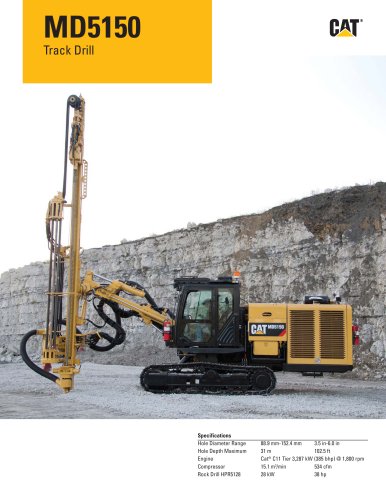

Cat® track drills MD5150

28 Seiten

-

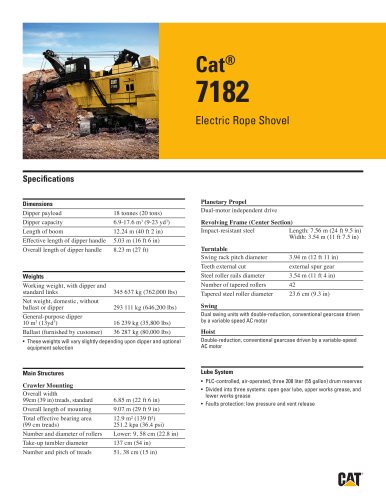

Electric Rope Shovels 7182

3 Seiten

-

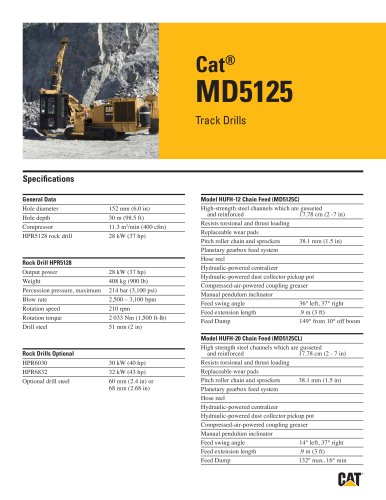

Cat® track drills MD5125

4 Seiten

-

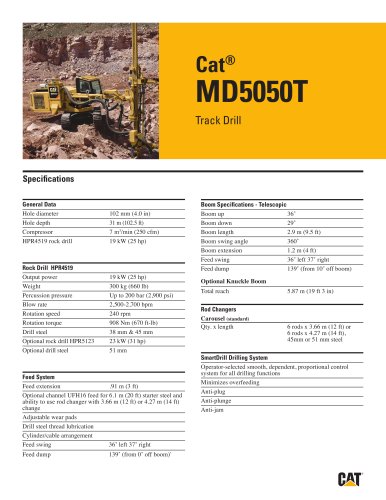

Cat® track drills MD5050 T

4 Seiten

-

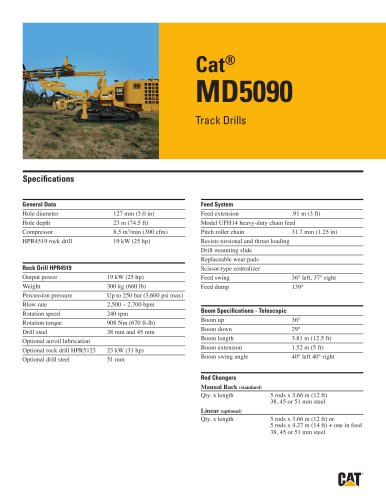

Cat® track drills MD5090

4 Seiten

-

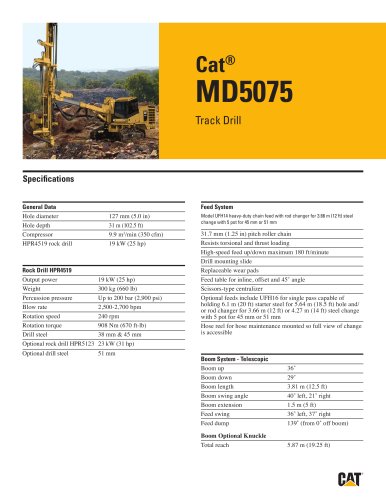

Cat® track drills MD5075

4 Seiten

-

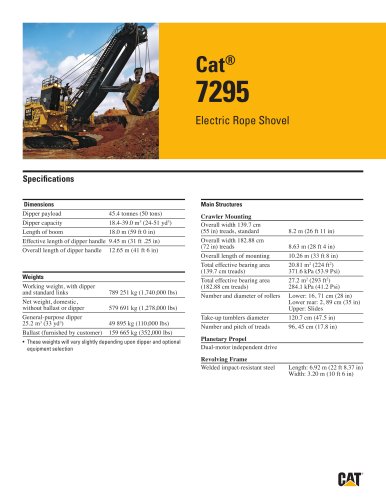

Electric Rope Shovels 7295

3 Seiten

-

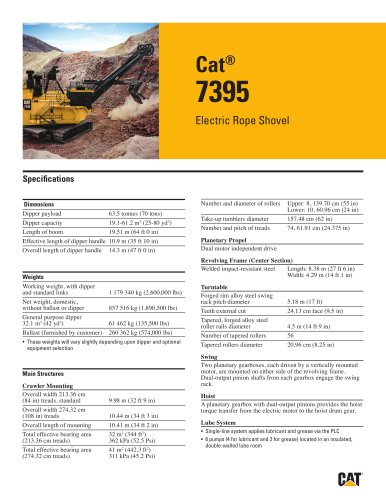

Electric Rope Shovels 7395

3 Seiten

-

Electric Rope Shovels 7295 HD

3 Seiten

-

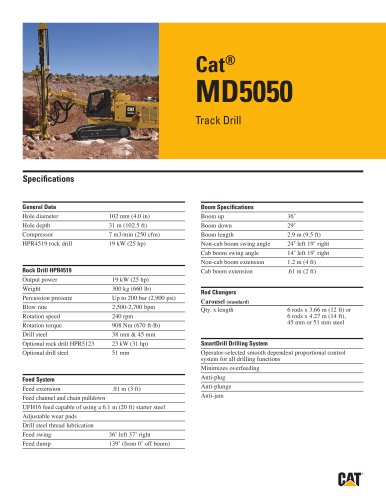

Cat® track drills MD5050

4 Seiten

-

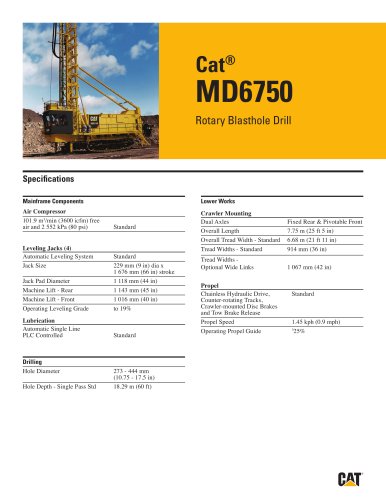

Cat® Rotary drills MD6750

4 Seiten

-

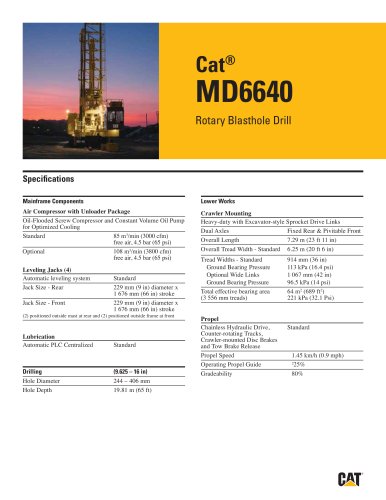

Cat® Rotary drills MD6640

4 Seiten

-

Electric Rope Shovels 7495 HD

3 Seiten

-

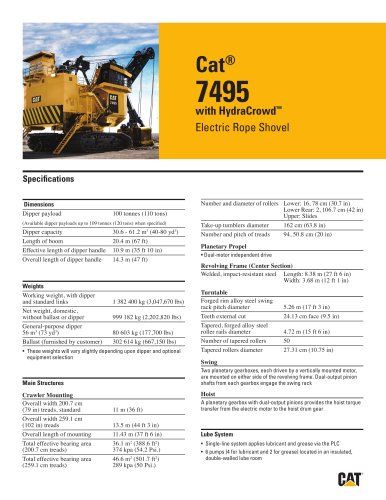

Electric Rope Shovels 7495

3 Seiten

-

Master Idler

399 Seiten

-

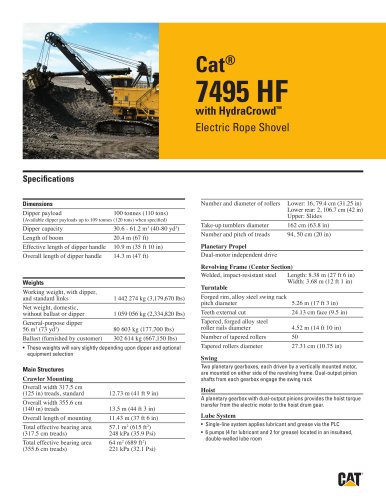

Electric Rope Shovels 7495 HF

3 Seiten

-

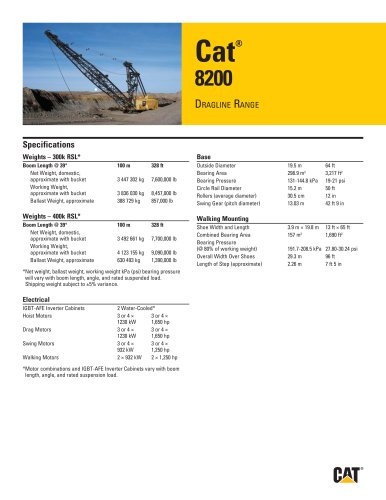

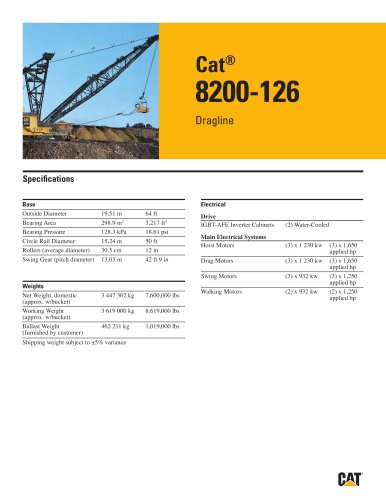

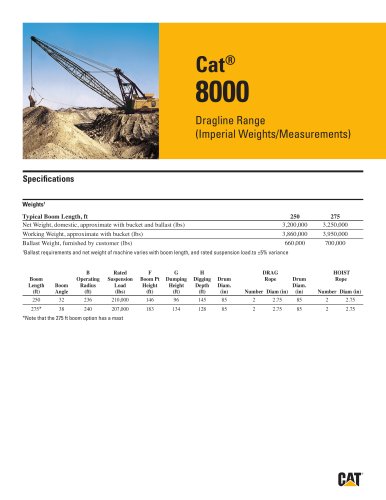

Cat® 8200 DRAGLINE RANGE

2 Seiten

-

Cat® 8200-127 Dragline

2 Seiten

-

Cat® 8200-126 Dragline

2 Seiten

-

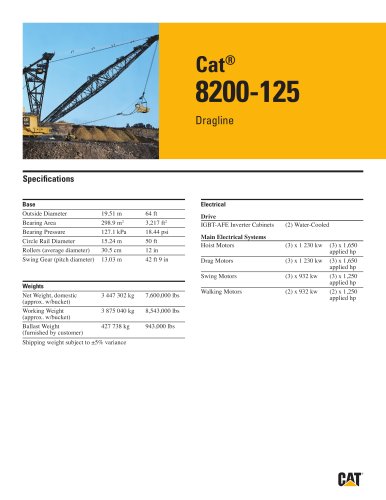

Cat® 8200-125 Dragline

2 Seiten

-

Cat® 8200-124 Dragline

2 Seiten

-

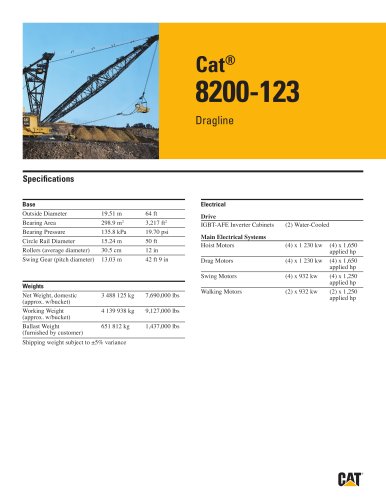

Cat® 8200-123 Dragline

2 Seiten

-

Cat® 8200-113 Dragline

2 Seiten

-

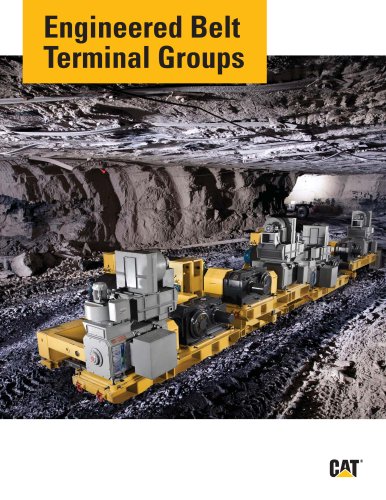

Engineered Belt Terminal Groups

4 Seiten

-

Belt systems and belt products

8 Seiten

-

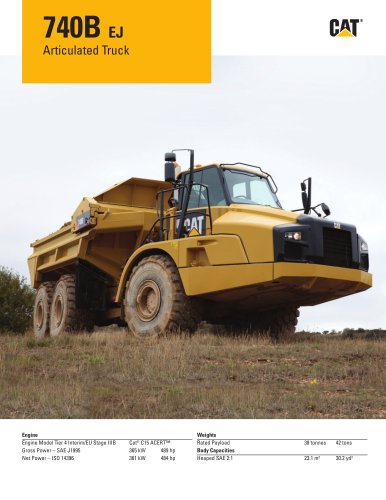

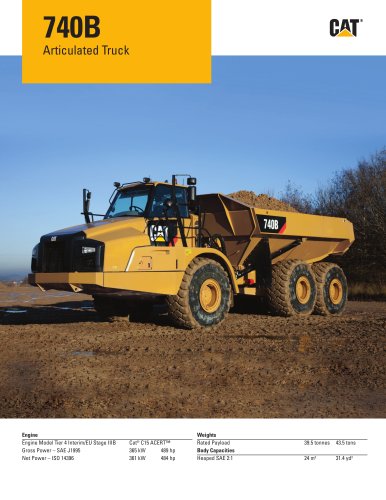

740B EJ articulated track

24 Seiten

-

740B articulated track

20 Seiten

-

730 ejector articulated track

20 Seiten

-

730 articulated track

20 Seiten

-

Feeder Breakers

4 Seiten

-

Belt Systems & Belt Products

8 Seiten

Archivierte Kataloge

-

Draglines

8 Seiten

-

988H Wheel Loader

24 Seiten

-

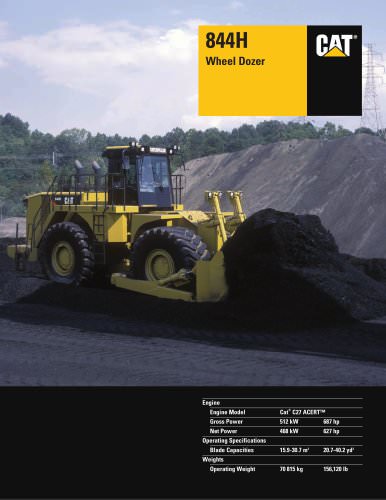

844H Wheel Dozer

20 Seiten

-

Scoops

8 Seiten

-

Face Haulers

12 Seiten

-

Continuous Miners

8 Seiten

-

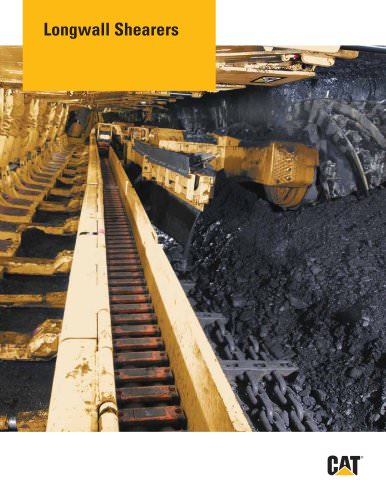

Longwall Shearers

16 Seiten

-

Roof Support Carriers

12 Seiten

-

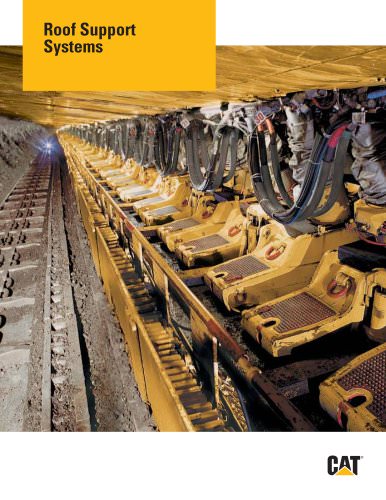

Roof Support Systems

8 Seiten

-

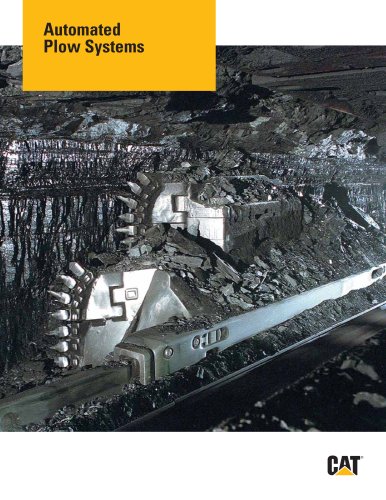

Automated Plow Systems

12 Seiten

-

Jumbo Drills

12 Seiten

-

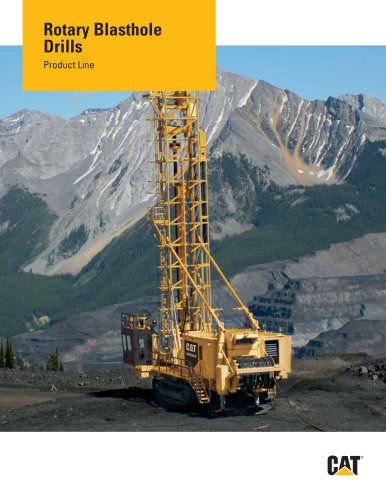

Rotary Blasthole Drills

8 Seiten

-

Hydraulic Track Drills

8 Seiten

-

Hydraulic Shovels

12 Seiten

-

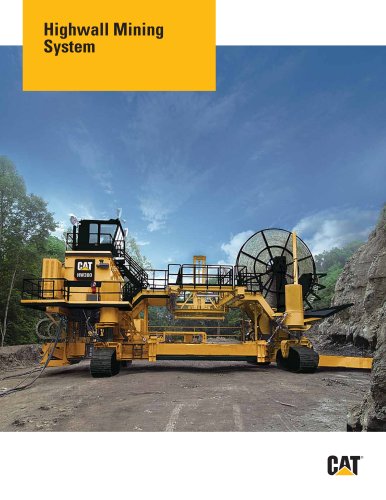

Highwall Mining System

8 Seiten

-

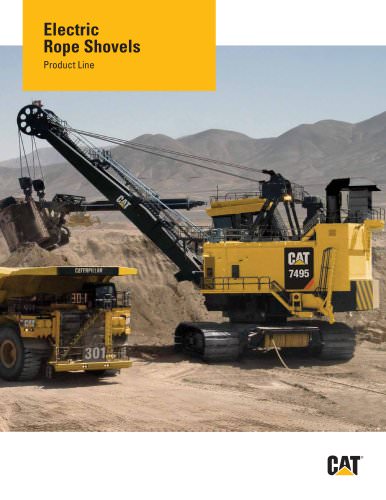

Electric Rope Shovels

12 Seiten

-

Surface Belt Structure

8 Seiten