Website:

Hennecke GROUP

Website:

Hennecke GROUP

Katalogauszüge

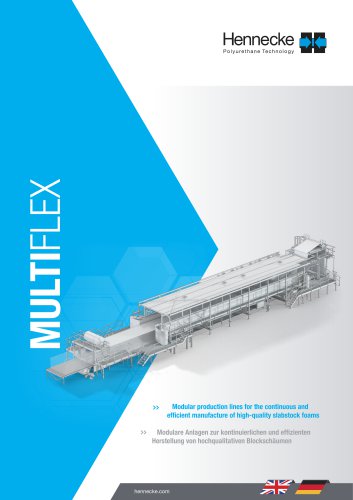

Modular production lines for the continuous and efficient manufacture of high-quality slabstock foams Modulare Anlagen zur kontinuierlichen und effizienten Herstellung von hochqualitativen Blockschäumen

Katalog auf Seite 1 öffnen

MULTIFLEX – SLABSTOCK PRODUCTION WITH MAXIMUM EFFICENCY MULTIFLEX - BLOCKSCHAUM-PRODUKTION MIT HÖCHSTER EFFIZIENZ For almost eight decades Hennecke has developed and produced high-quality plants for polyurethane processing. Hennecke is considered the market leader in the field of slabstock machinery and equipment. This know-how is reflected in the MULTIFLEX systems. The latest generation of one of the world's most renowned slabstock lines impresses processors with its attractive priceperformance ratio, which – thanks to a highly efficient raw material yield, outstanding foam qualities and the...

Katalog auf Seite 2 öffnen

FEATURES AUTO-FLAT (OPTIONAL) Benefit from the fully automated evolution to the FLATTOP system with a faster production start, greater production stability, and even better reproducibility. RISE PROFILE MEASUREMENT (OPTIONAL) Set the highest standards for consistent quality with a combination of laser distance sensors and a FOAMWARE plug-in to continuously compare the rise profile with defined reference curves. AUTO-FLAT (OPTIONAL) Profitieren Sie von der vollautomatischen Weiterentwicklung des FLAT-TOP-Systems mit einem schnelleren Produktionsstart, höherer Produktionsstabilität und noch...

Katalog auf Seite 3 öffnen

THE HIGH-PRESSURE PATH TO PROFITS Based on analyses and statements by leading slabstock foam producers and raw material manufacturers, the use of Hennecke high-pressure technology saves up to 5 percent isocyanate compared to low-pressure slabstock machines. With an annual slabstock foam production of 5,000 tonnes and an isocyanate price of EUR 3.00/kg, this corresponds to a saving of around EUR 200,000 per year. A further considerable cost saving results from the use of the proven LIQUID-LAYDOWN system together with the Hennecke rectangular process (FLAT-TOP system). 4-sided paper covering...

Katalog auf Seite 4 öffnen

Efficient raw material yield thanks to the combination of LIQUID-LAYDOWN, FLAT-TOP and 4-sided paper covering. Effiziente Rohstoffausbeute durch Kombination von LIQUID- LAYDOWN, FLAT-TOP und 4-Seiten-Paperiabdeckung. SAFELY INTO THE (PRODUCTION) FUTURE THROUGH CONTINUOUS FURTHER DEVELOPMENT: THE MACHINE FEATURES SICHER IN DIE (PRODUKTIONS-) ZUKUNFT DURCH STÄNDIGE WEITERENTWICKLUNG: DIE MASCHINENMERKMALE MULTIFLEX lines are equipped with high-quality standard components. High-quality and robust system components are part and parcel of MULTIFLEX plants. Especially in the field of metering...

Katalog auf Seite 5 öffnen

THE BASIS FOR HIGH-GRADE FOAM: THE DYNAMIC MSL STIRRER MIXER One key factor that ensures high-quality and efficient processing of polyurethane is mixhead technology. Hennecke has outstanding expertise in this area and makes its mixheads (apart from a few standard parts) in its own manufacturing halls. This guarantees the highest quality and performance. The height-adjustable mixer unit of the MULTIFLEX series is the heart of the system. This powerhouse combines injection and stirrer principles with precise laminar liquid distribution through our calibration unit. The result? Exceptional foam...

Katalog auf Seite 6 öffnen

ADVANCED CELL CONTROL ERWEITERTE ZELL-KONTROLLE HIGH PRESSURE ISOCYANATE INJECTION A micro-fine spray effect in the mixing chamber leads to a significantly improved chemical reaction and better control over the cell size. In addition, isocyanate consumption is reduced by up to 5 %. ISOCYANAT-HOCHDRUCK-INJEKTION Ein mikrofeiner Sprüheffekt in der Mischkammer führt zu einer deutlich verbesserten chemischen Reaktion und einer besseren Kontrolle über die Zellgröße. In Folge wird der Isocyanat-Verbrauch um bis zu 5 Prozent reduziert. SPOUT-EX (OPTIONAL) Effective extension for MSL agitator heads,...

Katalog auf Seite 7 öffnen

Depending on the plant configuration, the MULTIFLEX series can be used to produce a wide variety of polyether-based slabstock foams with uniform hardness and density distribution. Besides the commercial foam types for the upholstery and mattress industry, MULTIFLEX slabstock is ideally suitable for technical items and for cutting into sheeting of any desired thickness. Patented NOVAFLEX® technology, utilizing the blowing agent CO2 makes it possible to manufacture foams with low densities of up to 14 kg/m3. This process does not only fulfill qualitative and economic criteria, it also meets...

Katalog auf Seite 8 öffnen

HIGH PRECISION AND RELIABILITY: THE HENNECKE HIGH-PRESSURE METERING SYSTEM PRÄZISE UND SICHER: DAS HENNECKE-HOCHDRUCK-DOSIERSYSTEM The MULTIFLEX uses precision high-pressure pumps with large adjustment ranges to produce high-grade slabstock. All metering lines are equipped with recirculation systems for preliminary adjustments and formulation changes. Exactly reproducible metering outputs of the pumps and computer-controlled volume flow measurement ensure additional production stability. The number of metering units and the metering outputs in the standard configuration can be extended and...

Katalog auf Seite 9 öffnen

EVERYTHING IN SIGHT: AUTOMATED PROCESS CONTROL ALLES IM BLICK: AUTOMATISIERTE PROZESSKONTROLLE The FOAMWARE is specially tailored to requirements of slabstock foamers. We have enhanced the proven functions of the previous generation PDE with a number of new features. Even in the standard version, the FOAMWARE includes visualized flow charts, process charts and calibration history, as well as further software tools for analyzing the actual and setpoint values. The FOAMWARE's "magic eye" function also makes it easier to identify any irregularities by displaying the pressure data in a graph....

Katalog auf Seite 10 öffnen

SYSTEM ADVANTAGES >> Highly efficient raw material yield and cost savings through: • Hennecke high-pressure technology for all components • 4-page paper system (including FLAT-TOP-System) • Recirculation for all metering lines • Availability of additional functions such as tilting side walls and pneumatic nozzles for all metering lines >> Hocheffiziente Rohstoffausbeute und Kosteneinsparung durch: • Hennecke-Hochdrucktechnik für alle Komponenten • 4-Seiten-Papiersystem (inkl. FLAT-TOP-System) • Rezirkulation für alle Dosierlinien • Verfügbarkeit von zusätzlichen Funktionen wie kippbare...

Katalog auf Seite 11 öffnenAlle Kataloge und technischen Broschüren von Hennecke GROUP

-

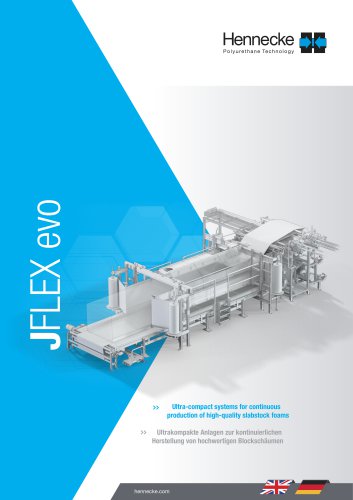

JFLEX evo

12 Seiten

-

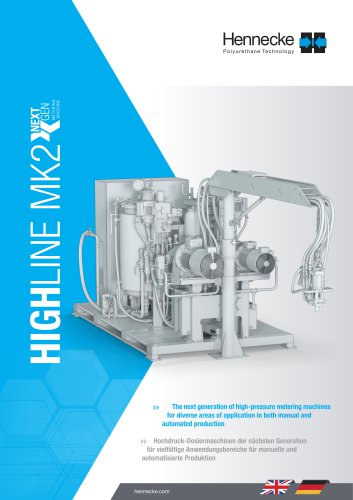

HIGHLINE MK2

12 Seiten

-

LABFOAM

4 Seiten

-

ROTAMAT

8 Seiten

-

KGS

10 Seiten

-

BLOCFOAMAT

6 Seiten

-

QFM

10 Seiten

-

MIXHEADS

3 Seiten

-

STREAMLINE MK2

24 Seiten

-

ELASTOLINE

10 Seiten

-

TOPLINE HK

8 Seiten

-

Fascination PUR Worldwide 2021

26 Seiten

-

Mischkopf Portfolio 2021

3 Seiten

-

MICROLINE

6 Seiten

-

TOPLINE MK2

12 Seiten

-

ELASTOLINE HP

2 Seiten

-

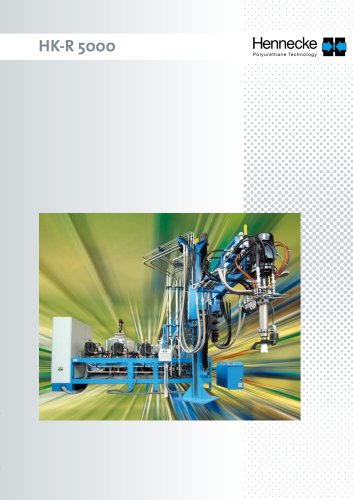

HK-R 5000

4 Seiten

-

JETLINE

12 Seiten

-

COLOURLINE

16 Seiten

-

ECOPLUS

8 Seiten

-

ECOPLUS MK2

8 Seiten

-

IMPACT

8 Seiten

-

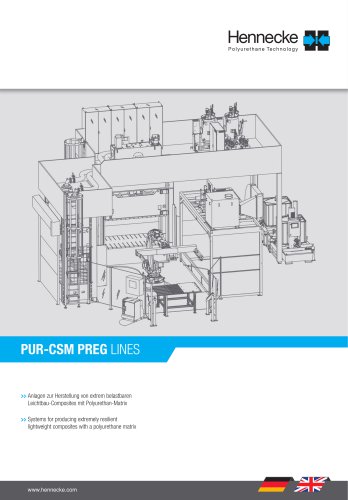

PUR-CSM PREG LINES

22 Seiten

-

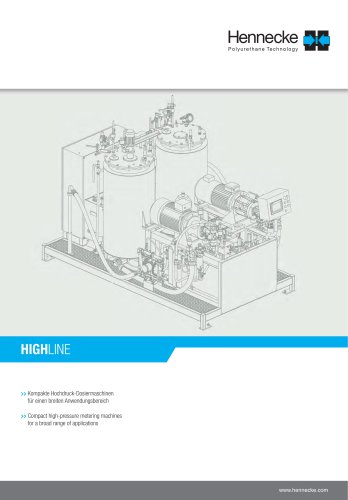

HIGHLINE

8 Seiten

-

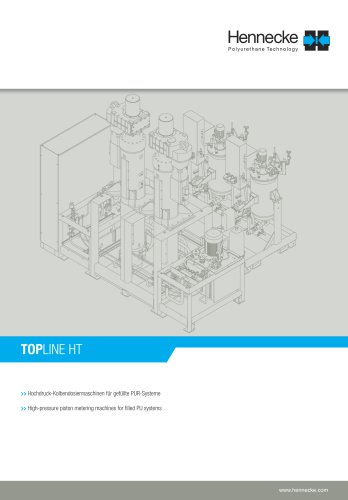

TOPLINE HT

4 Seiten

-

PUR-CSM SKIN LINES

10 Seiten

-

PUR-CSM SANITARY LINES

10 Seiten

-

PUR-CSM

10 Seiten