Katalogauszüge

of making processes work >

Katalog auf Seite 1 öffnen

ή Mass Flow Meter Inline Measuring System Continuous Solids Flow Feeding Gravimetric Feeders Precision measuringand metering in accordance with the Coriolis principle. With a flow-controlledprefeeder it becomesa feeding system. Compact inline measuring systembased on the impact plate principle, for the continuous acquisition of flow rates. MULTISTREAM Mass flow measuring according to thedeflector measuring principle in a compact design. MULTISTREAM The modular dosing system for a widerange, with integrated measurement,control and regulation electronics.For feeding of anti-caking material to...

Katalog auf Seite 2 öffnen

Universal Big-Bag Emptying Station Suitable for flow rates of up to20,000 t/hr with an accuracy of up to 0.25 %. The legal-for-tradeversion is suitable for IEC beltwidths. Thanks to its modular designthe SacMaster Weighbelt For Flushing Material Continuous Bulk Solids Measurement in Belt Conveyor Systems Two weighing modules ensure reliableload measuring. Belt-run monitoring avoids calculation errors. Automatic belt tensioning and tracking device ensures constant belt tension. Special belt for weighing tasks,endless vulcanised. Rugged weighfeederdesign, suitable for use in aggressive atmo-...

Katalog auf Seite 3 öffnen

Typical requirements on the equipment Electronics Our electronic controllers of the DISOMAT Rugged weighfeeder design Resistance against a very dusty and chemically aggressive ambiance, i.e. requiringspecial painting as well as connecting elements, carrying idlers and weighing modules of stainless steel, appliance completely made of stainless steel > , DISOCONT > ή , INTECONT > and DISOCONT > ή Master ranges ensurea trouble-free interface with the plants process control system. Clean scale environment Dust-tight housing Electronics separated from the mechanics (control cubicle in a safe...

Katalog auf Seite 4 öffnen

Schenck Process demonstrates its expertise not only in individual products andapplications but also in providing complete systems from planning to execution.Various raw materials are discharged from silos with the aid of feed units and fed ontoa collecting belt via weighfeeders. Conveyor belts and elevators transfer the batched raw materials to an intermediate hopper continuously feeding a mixer. > Chain ElevatorBelt Weighers Weighfeeders PASS: Customised to meet your requirements, our comprehensive Process Advanced Service System provides you with the best service: > P A S S F u l l S e...

Katalog auf Seite 5 öffnenAlle Kataloge und technischen Broschüren von Schenck Process Holding GmbH

-

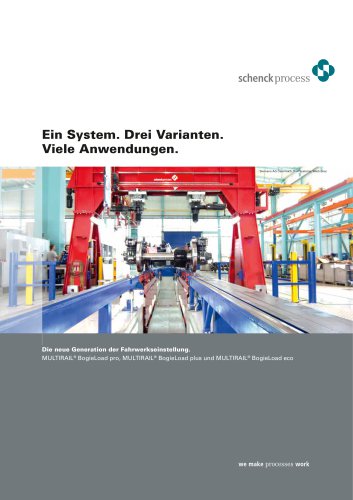

MULTIRAIL® BogieLoad pro

20 Seiten

-

MULTIRAIL®

16 Seiten

-

overview

20 Seiten

-

Ihr Weg zu Schenck Process

4 Seiten

-

LinaClass® screens

6 Seiten

-

CONiQ®

12 Seiten

-

Reliability in pet food production

12 Seiten

-

Food industry

20 Seiten

-

Components Catalog

216 Seiten

-

Cement industry

16 Seiten

-

TEDO Förderer

7 Seiten

-

SPro screen panels

12 Seiten

-

LinaClass®

6 Seiten

-

LOGiQ® loading automation

10 Seiten

-

Power industries

16 Seiten

-

MULTIRAIL® BogieLoad Produktfamilie

20 Seiten

-

IDMS Durchblas Messerschleuse

2 Seiten

-

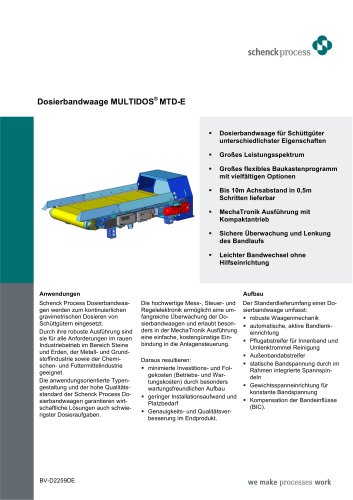

MULTIDOS® H Dosierbandwaage

2 Seiten

-

MULTIDOS® E Dosierbandwaage

4 Seiten

-

SacMaster

1 Seiten

-

AccuRate® Volumetrische Dosierer

1 Seiten

-

MULTIDOS® VDP

2 Seiten

-

Komponenten und Standardprodukte

206 Seiten

-

DISOCONT®

4 Seiten

-

MULTIBELT®

4 Seiten

-

MULTICOR® S

1 Seiten

-

Smart Dust Collection Solution

12 Seiten

-

Precise feeding solutions

4 Seiten

-

FulFiller ®

8 Seiten

-

MULTIBELT® Belt Weigher

8 Seiten

-

CONiQ® Cloud

1 Seiten

-

Pharmaceutical industry

10 Seiten

-

Material Handling Solutions

8 Seiten

-

Capabilities of Stock

8 Seiten

-

Screenex® screening media

24 Seiten

-

Enduro isolation springs

4 Seiten

-

MCPP

12 Seiten

-

ModuPlasma

8 Seiten

-

Airlocks and Diverter Valves

6 Seiten

-

MaxiStore®

8 Seiten

-

SacMaster®

8 Seiten

-

Screen Rebuild Program

4 Seiten

-

MultiTrain® Technology

4 Seiten

-

Training that delivers!

38 Seiten

-

IntraBulk bulk reception unit

8 Seiten

-

MoveMaster® chain conveyors

8 Seiten

-

ProPulse Industrial Air Filters

12 Seiten

-

Drop forged chain

8 Seiten

-

RoCon® Series 6

8 Seiten

-

Sustainable Cement Production

10 Seiten

-

Under the harshest conditions

16 Seiten

-

Tidal Series 5

6 Seiten

-

Screen rebuilding

4 Seiten

-

RotoScrew

2 Seiten

-

Rotofeed Pneumatic Injector

2 Seiten

-

DWB

4 Seiten

-

MultiFlex

4 Seiten

-

Stock Forry® ESP Products

8 Seiten

-

Air pollution control

4 Seiten

-

Stock Valves

8 Seiten

-

IntraBulk - Bulk Reception Unit

8 Seiten

-

Product Overview

8 Seiten

Archivierte Kataloge

-

We make processes work

20 Seiten

-

MULTIRAIL® WheelLoad

2 Seiten

-

MULTIRAIL® WheelScan

2 Seiten

-

MULTIRAIL® MultiBridge

2 Seiten

-

MULTIRAIL® LiquidWeight

2 Seiten

-

MULTIRAIL® LegalWeight

2 Seiten

-

MULTIDOS® L

4 Seiten

-

MULTIGRAV®

4 Seiten

-

ProFlex® C

2 Seiten

-

Funk-Service-Bedienkonzept

2 Seiten

-

DISOMAT® Tersus

4 Seiten

-

DISOMAT® Satus

4 Seiten

-

DISOMAT® B plus Ex, Zone 1

4 Seiten

-

INTECONT® Opus

4 Seiten

-

Wägesensoren

1 Seiten

-

Kreiserregerzellen

4 Seiten

-

Durchblas Messerschleuse IDMS

2 Seiten

-

MULTISTREAM® G

4 Seiten

-

MULTISTREAM® B

4 Seiten

-

MULTICOR®R 450

4 Seiten

-

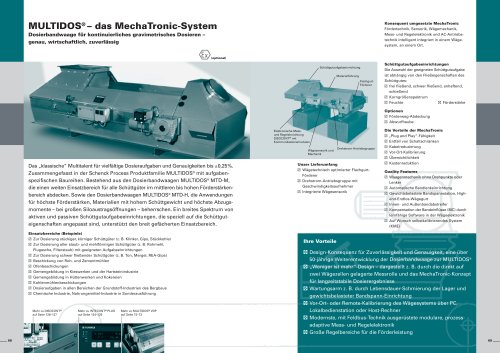

MULTIDOS® E

4 Seiten

-

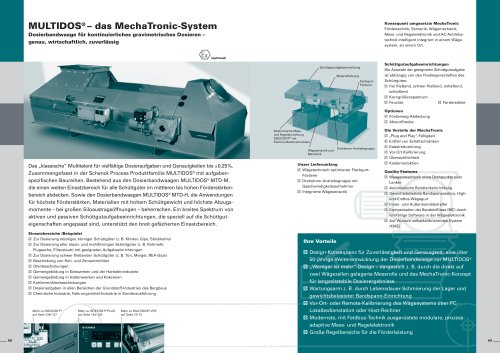

MULTIDOS® M

4 Seiten

-

Award Winning Solutions

6 Seiten

-

We make processes work_2012

16 Seiten

-

Force exciters

4 Seiten