Katalogauszüge

Competence in Cement we make >

Katalog auf Seite 1 öffnen

Perfectly mixed, fed accurately and without pulsation,precisely weighed Quality meets Qualityԓ Perfect cement is the result of four overlappingprocesses where Schenck Process measuring and feeding devices with optimally integrated weighing technology play a major role. Process Step 1: Limestone is mined at a quarry, crushed into small pieces, and stored in blending beds. Schenck Process MULTIBELT > belt scales recordmaterial quantities accurately and reliably under harsh conditions. Process Step 2: The crushed limestone is ground into raw meal. Additives, such as clay, sand, or iron ore,...

Katalog auf Seite 2 öffnen

apron conveyor > belt scale limestonesandclay dryerlimestone crusher claysand > sweeping wheel crusherrelief screenMULTIBELT limestone claysand > ή solid flow measuringdevice separator > weighfeeders orapron weighfeeder MULTISTREAM homogeni-zationflow gates MULTIDOS raw mill bucket elevator Process Steps 3 and 4 on pages 50Ζ51 >

Katalog auf Seite 3 öffnen

Perfectly mixed, fed accurately and without pulsation,precisely weighed Quality meets QualityӔ Process Step 3: The raw mix is placed in rotary kilns and burnt at over 1,000 Cto produce clinker. Different types of pulverized coal or secondary fuels are used to heat the kiln. Schenck Process MULTICOR > Ю mass flow feedingsystems can meter pulverized coal efficiently and without pulsation directly into the pneumatic lines that lead to the main burner (at the discharge end of the kiln) and the calcinator (at the feed end of the kiln). Schenck Process's semi-mobile compact system can meter...

Katalog auf Seite 4 öffnen

Process Steps 1 and 2on pages 4849 dust and meal feeding Primary andsecondary fuel feeding > ֮ Smass flow feeding devicerawmeal MULTICOR clinkergypsum additives or MULTISTREAM > solid flow feeding device MULTICOR fly ashrotary kiln MULTICOR > MULTIDOS ή weighfeeder orproportioning apron weighfeeder > Sfuels cooler calcinator MULTICOR > ή Smass flow feeding device storage silo separatorbucketelevator end product cement mill mixing and loading utilizing weighing technology truck scales > K mass flowfeeding system LAS loadinglogistics solutions >

Katalog auf Seite 5 öffnen

Guaranteed feeding constancy for high product quality,efficient kiln operation and optimal emission values > Applications: Primary materials ֖ perfectlyfed and flexibly composed Pulverized coal types, such as lignite, anthracite, charcoal, bituminous coal, oil coke, or mixtures of these fuels are used, as are oil shale, coke, and pulverized anodes, further broadening the spectrum of materials. Rotary kiln charging in cementplants (main burner and calcinator) Rotary kiln charging in lime plants (main burner) Shaft kiln charging in cement or lime plants Feeding of pre-heaters or reactors...

Katalog auf Seite 6 öffnen

Two Basic Feeding Concepts > Feeding the burner at medium pneumatic transferpressuresFeeding the burner at very hightransfer pressures 1. Direct feeding into the pneumatic conveyor line using MULTICOR 2. Indirect feeding via a pump or starfeeder into the pneumatic conveyor line using MULTICOR K and MULTICELL. ή S and MULTICELL. typical inlet = 700 mm MULTICELL(Feeder) MULTICOR typical inlet = 700 mmMULTICELL(Feeder) MULTICOR typicalheightapprox.10.5 m 踮 S Pump KDirection of flow typical heightapprox.3.15 m Advantages High feeding constancy for economical kiln operation Pulsation-free...

Katalog auf Seite 7 öffnen

Weighfeeder 4 > Tractor-trailer with֓walking floor 1 3 > Blow-through chain conveyor 5 > Blow-through star feeder 2 > Docking station withlive bottom bin 6 > Pneumatic conveyor line

Katalog auf Seite 8 öffnen

Getting the job done with a minimum of investment (2) (1) with ֓walking floors. The vehicles are docked atthe two unloading stations for this purpose. Via the extraction screws and the troughed chain conveyor (3) , the materialis fed to the MULTIDOS Neither reserve silos nor structural changes are required atthe site for the semi-mobile system, and it only requires 9 x 6 m of space. The secondary fuels are discharged directly from tractor- trailers (5) , where it is conveyed directly to the burner > Ԯ weighfeeder (4) . The weighfeederfeeds the appropriate amount of fuel into the...

Katalog auf Seite 9 öffnen

Module 1: Mass flow measurement with MULTICOR > ֮ S >

Katalog auf Seite 10 öffnen

Prefeeders, depending on the bulk material properties (module 2) Flow gate (position-controlled) for materials with free flowing properties; for applications up to approx. 800 m > 3 /h Star feeders (speed-controlled) for materials with free flowing properties; for applications up to approx. 120 m > 3 /h Feeding screws (speed-controlled) with integrated agitator for materials with free to moderate flowing properties for applications up to approximately 120 m > 3 /h Applications for complete solutions > Module 2: Powderdust:main portion < 0.1 mm, max. grain size 1 mm(some individual particles...

Katalog auf Seite 11 öffnen

System Set-up: MULTICOR > ֮ S feeds the exact proportion of theprimary component needed as part of the total flow rate for all materials comprising the mixture.As a prefeeder, we recommend a speed-controlled screw, a star feeder, or a position- controlled flow gate, depending on the material, desired feed rate, and flow properties.The additives are fed directly from the slavefeeding system to the MULTICOR > measuringwheel. Depending on the desired feed rate and the material flow properties, either the MechaTron > ή Loss-in-Weight Feeder or theMULTICOR > feeding system is used. For the...

Katalog auf Seite 12 öffnen

Possible Applications: Feeding of chunky, granular bulk materials (e.g., clinker, gypsum, lump coal) Feeding of all powdery or mealy bulk solids (e.g., raw meal, fly ash, filter dust) with appropriate charging devices Feeding of poorly flowing bulk materials (e.g., clay, marl, gypsum from flue gas desulfurization systems) Charging of raw and cement mills Kiln charging Mixture formation in gravel quarries and in the hard stone industry Mixture formation in smelting and coke plants Coal mill charging Feeding tasks in all mining-related industries Chemical industry, food industry (special...

Katalog auf Seite 14 öffnenAlle Kataloge und technischen Broschüren von Schenck Process Holding GmbH

-

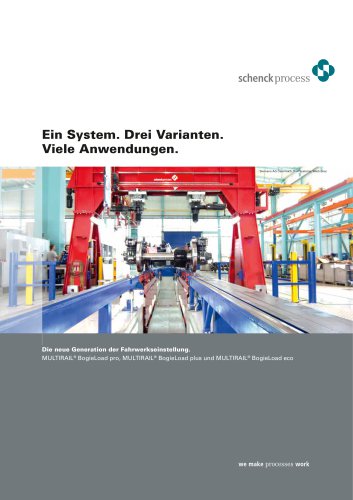

MULTIRAIL® BogieLoad pro

20 Seiten

-

MULTIRAIL®

16 Seiten

-

overview

20 Seiten

-

Ihr Weg zu Schenck Process

4 Seiten

-

We make processes work

20 Seiten

-

LinaClass® screens

6 Seiten

-

CONiQ®

12 Seiten

-

Reliability in pet food production

12 Seiten

-

Food industry

20 Seiten

-

Components Catalog

216 Seiten

-

Cement industry

16 Seiten

-

TEDO Förderer

7 Seiten

-

SPro screen panels

12 Seiten

-

LinaClass®

6 Seiten

-

LOGiQ® loading automation

10 Seiten

-

Power industries

16 Seiten

-

MULTIRAIL® BogieLoad Produktfamilie

20 Seiten

-

IDMS Durchblas Messerschleuse

2 Seiten

-

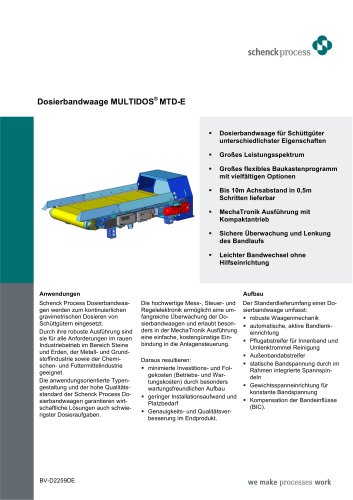

MULTIDOS® H Dosierbandwaage

2 Seiten

-

MULTIDOS® E Dosierbandwaage

4 Seiten

-

SacMaster

1 Seiten

-

AccuRate® Volumetrische Dosierer

1 Seiten

-

MULTIDOS® VDP

2 Seiten

-

Komponenten und Standardprodukte

206 Seiten

-

DISOCONT®

4 Seiten

-

MULTIBELT®

4 Seiten

-

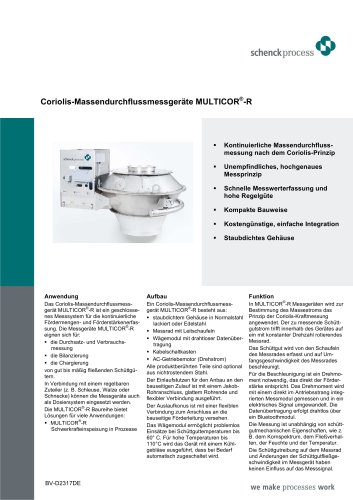

MULTICOR® S

1 Seiten

-

Smart Dust Collection Solution

12 Seiten

-

Precise feeding solutions

4 Seiten

-

FulFiller ®

8 Seiten

-

MULTIBELT® Belt Weigher

8 Seiten

-

CONiQ® Cloud

1 Seiten

-

Pharmaceutical industry

10 Seiten

-

Material Handling Solutions

8 Seiten

-

Capabilities of Stock

8 Seiten

-

Screenex® screening media

24 Seiten

-

Enduro isolation springs

4 Seiten

-

MCPP

12 Seiten

-

ModuPlasma

8 Seiten

-

Airlocks and Diverter Valves

6 Seiten

-

MaxiStore®

8 Seiten

-

SacMaster®

8 Seiten

-

Screen Rebuild Program

4 Seiten

-

MultiTrain® Technology

4 Seiten

-

Training that delivers!

38 Seiten

-

IntraBulk bulk reception unit

8 Seiten

-

MoveMaster® chain conveyors

8 Seiten

-

ProPulse Industrial Air Filters

12 Seiten

-

Drop forged chain

8 Seiten

-

RoCon® Series 6

8 Seiten

-

Sustainable Cement Production

10 Seiten

-

Under the harshest conditions

16 Seiten

-

Tidal Series 5

6 Seiten

-

Screen rebuilding

4 Seiten

-

RotoScrew

2 Seiten

-

Rotofeed Pneumatic Injector

2 Seiten

-

DWB

4 Seiten

-

MultiFlex

4 Seiten

-

Stock Forry® ESP Products

8 Seiten

-

Air pollution control

4 Seiten

-

Stock Valves

8 Seiten

-

IntraBulk - Bulk Reception Unit

8 Seiten

-

Product Overview

8 Seiten

Archivierte Kataloge

-

MULTIRAIL® WheelLoad

2 Seiten

-

MULTIRAIL® WheelScan

2 Seiten

-

MULTIRAIL® MultiBridge

2 Seiten

-

MULTIRAIL® LiquidWeight

2 Seiten

-

MULTIRAIL® LegalWeight

2 Seiten

-

MULTIDOS® L

4 Seiten

-

MULTIGRAV®

4 Seiten

-

ProFlex® C

2 Seiten

-

Funk-Service-Bedienkonzept

2 Seiten

-

DISOMAT® Tersus

4 Seiten

-

DISOMAT® Satus

4 Seiten

-

DISOMAT® B plus Ex, Zone 1

4 Seiten

-

INTECONT® Opus

4 Seiten

-

Wägesensoren

1 Seiten

-

Kreiserregerzellen

4 Seiten

-

Durchblas Messerschleuse IDMS

2 Seiten

-

MULTISTREAM® G

4 Seiten

-

MULTISTREAM® B

4 Seiten

-

MULTICOR®R 450

4 Seiten

-

MULTIDOS® E

4 Seiten

-

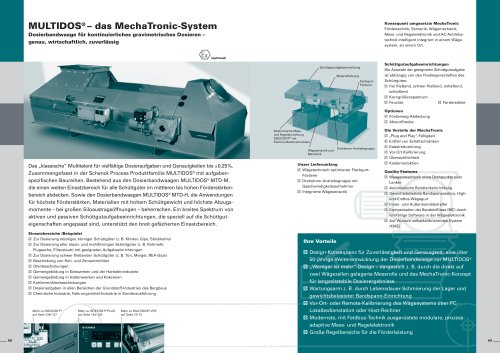

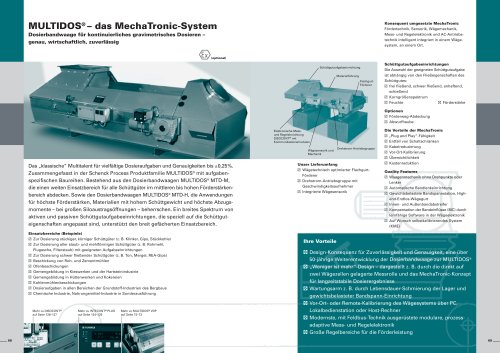

MULTIDOS® M

4 Seiten

-

Award Winning Solutions

6 Seiten

-

We make processes work

16 Seiten

-

Force exciters

4 Seiten