Katalogauszüge

PET Pressure transmitter Druckmessumformer SICK Sensor Intelligence.

Katalog auf Seite 1 öffnen

GB Operating instructions PET D Betriebsanleitung PET

Katalog auf Seite 2 öffnen

Operating Instructions Contents PET Operating Instructions Contents PET Inhalt Seiten 24-43 DE 8014827/2012/04/17 • AA • (2012-04) © SICK AG • Germany • All rights reserved • Subject to change without notice 3

Katalog auf Seite 3 öffnen

Operating Instructions 1. General Information PET 1. General Information ■ The pressure transmitter described in the operating instructions has been designed and manufactured using state-of-the-art technology. All components are subject to stringent quality and environmental criteria during production. Our management systems are certified to ISO 9001 and ISO 14001. ■ These operating instructions contain important information on handling the instrument. Working safely requires that all safety instructions and work instructions are observed. ■ Observe the relevant local accident prevention...

Katalog auf Seite 4 öffnen

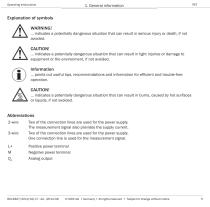

Operating Instructions 1. General Information PET Explanation of symbols WARNING! / J \ ... indicates a potentially dangerous Situation that can result in serious injury or death, if not avoided. A CAUTION! / | \ ... indicates a potentially dangerous Situation that can result in light injuries or damage to ' * ' equipmentorthe environment, if not avoided. Information ... points out useful tips, recommendations and Information for efficient and trouble-free Operation. A CAUTION! ... indicates a potentially dangerous Situation that can result in burns, caused by hot surfaces i ~ » or...

Katalog auf Seite 5 öffnen

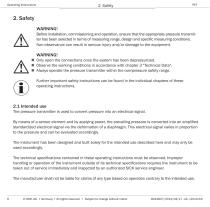

Operating Instructions Before installation, commissioning and operation, ensure that the appropriate pressure transmitter has been selected in terms of measuring range, design and specific measuring conditions. Non-observance can result in serious injury and/or damage to the equipment. Only open the connections once the system has been depressurized. Observe the working conditions in accordance with chapter 3 "Technical Data". Always operate the pressure transmitter within the overpressure safety range. Further important safety instructions can be found in the individual chapters of these...

Katalog auf Seite 6 öffnen

Operating Instructions 2. Safety PET Operating Instructions 2. Safety PET 2.2 Personnel qualification WARNING! Risk of injury should qualification be insufficient! Improper handling can result in considerable injury and damage to equipment. The activities described in these operating instructions may only be carried out by skilled personnel who have the qualifications described below. Skilled personnel Skilled personnel are understood to be personnel who, based on their technical training, knowledge of measurement and control technology and on their experience and knowledge of...

Katalog auf Seite 7 öffnen

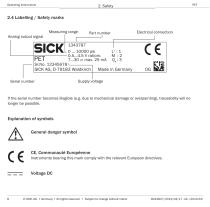

Operating Instructions 2. Safety PET 2.4 Labelling / Safety marks Operating Instructions 2. Safety PET Analog output signal Measuring range Electrical connection Serial number Supply voltage If the serial number becomes illegible (e.g. due to mechanical damage or overpainting), traceability will no longer be possible. Explanation of symbols General danger symbol CE, Communaute Europeenne Instruments bearing this mark comply with the relevant European directives. Voltage DC © SICK AG • Germany • All rights reserved • Subject to change without notice

Katalog auf Seite 8 öffnen

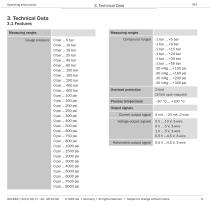

Operating Instructions 3. Technical Data PET Measuring ranges Gauge pressure 8014827/2012/04/17 • AA • (2012-04) © SICK AG • Germany • All rights reserved • Subject to change without notice 9

Katalog auf Seite 9 öffnen

Operating Instructions 3. Technical Data PET Process connections 3.3 Mechanics / electronics G 1/8 B according to EN 837 (up to 400 bar / 5000 psi) G 1/4 A according to DIN 3852-E G 1/4 B according to EN 837 G 1/4 female according to EN 837 G 3/8 B according to EN837 1/8” NPT (up to 400 bar / 5000 psi) 1/4” NPT 1/4” NPT female R 1/4 according to ISO 7 R 3/8 according to ISO 7 7/16”-20 UNF SAE #4 J514 male with O-ring Boss (FKM) 9/16”-18 UNF SAE #4 J514 male with O-ring Boss (FKM) NBR 11 FPM/FKM 21 Without seal 11 Only for process connection G 1/4 A according to DIN 3852-E. 2) Only for...

Katalog auf Seite 10 öffnen

Operating Instructions 3. Technical Data PET 3) Available upon request for process connections G 1/4 A according to DIN 3852-E, 1/4”NPT, R 1/4 according to ISO 7, and 7/16”-20 UNF. 4) According to IEC 60529. The enclosure rating classes specified only apply while the sensor is connected with female connectors that provide the corresponding enclosure rating. 5) Electrical circuit in accordance with section 9.3 of UL/EN/IEC 61010-1 or an LPS to UL/EN/ IEC 60950-1 or class 2 in accordance with UL1310/UL1585 (NEC or CEC). The power supply must be suitable for operation above 2,000 m should the...

Katalog auf Seite 11 öffnen

Operating Instructions 3. Technical Da ta PET 3.4 Ambient Data Ambient temperature operation © SICK AG • Germany • All rights reserved • Subject to change without notice

Katalog auf Seite 12 öffnen

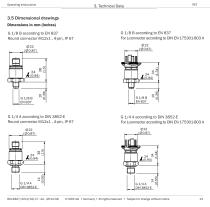

Operating Instructions 3.5 Dimensional drawings Dimensions in mm (inches) G 1/8 B according to EN 837 Round connector M12x1 , 4-pin, IP 67 22 0.87) G 1/4 A according to DIN 3852-E Round connector M12x1 , 4-pin, IP 67 22 0.87) G 1/4 A according to DIN 3852-E For L-connector according to DIN EN 175301-803 A G 1/8 B according to EN 837 For L-connector according to DIN EN 175301-803 A © SICK AG • Germany • All rights reserved • Subject to change without notic

Katalog auf Seite 13 öffnen

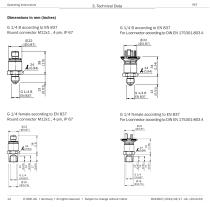

Operating Instructions 3. Technical Data G 1/4 B according to EN 837 For L-connector according to DIN EN 175301-803 A G 1/4 female according to EN 837 Round connector M12x1 , 4-pin, IP 67 G 1/4 female according to EN 837 For L-connector according to DIN EN 175301-803 A G 1/4 B according to EN 837 Round connector M12x1 , 4-pin, IP 67 © SICK AG • Germany • All rights reserved • Subject to change without notice

Katalog auf Seite 14 öffnen

Operating Instructions Dimensions in mm (inches) 1/4‘‘ NPT Round connector M12x1 , 4-pin, IP 67 22 0.87) 1/4‘‘ NPT female For L-connector according to DIN EN 175301-803 A ( © SICK AG • Germany • All rights reserved • Subject to chan

Katalog auf Seite 15 öffnenAlle Kataloge und technischen Broschüren von SICK

-

W4F de

17 Seiten

-

IMS de

12 Seiten

-

SLG-2 de

14 Seiten

-

IO-Link Supplement

5 Seiten

-

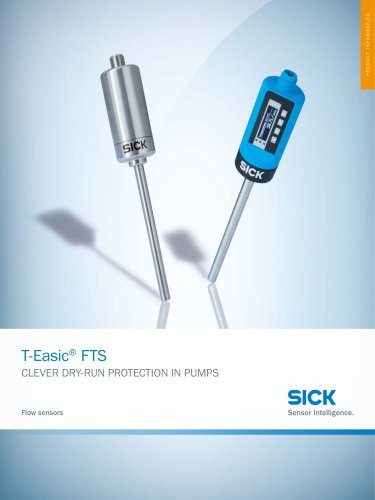

T-Easic FTS

56 Seiten

-

Fluidsensorik Produkte im Überblick

16 Seiten

-

T-Easic® FTS

4 Seiten

-

SPEETEC

2 Seiten

-

midiCam

5 Seiten

-

W4-3 PTFE

4 Seiten

-

Photoelektrische Lasersensoren

20 Seiten

-

SMART SENSORS

28 Seiten

-

Lichttaster und Lichtschranken_2019

20 Seiten

-

Safe Robotics Area Protection

32 Seiten

-

ENCODER UND NEIGUNGSSENSOREN

40 Seiten

-

EDS/EDM35

13 Seiten

-

G2F Photoelectric sensors

20 Seiten

-

TR110 Lock

20 Seiten

-

24-h-Helpdesk

8 Seiten

-

outdoorScan3

20 Seiten

-

EnforceKey Single Door

84 Seiten

-

LD-LRS Laser Measurement System

6 Seiten

-

T-Verteiler mit Taster

8 Seiten

-

Registration Sensors

24 Seiten

-

Top-Produkte von SICK

556 Seiten

-

Automatisierungs-Lichtgitter

228 Seiten

-

FL Rohgasmessung

2 Seiten

-

Produktinformation GR18

56 Seiten

-

Katalog Lichttaster und Lichtschranken

932 Seiten

-

SICK Kompact

118 Seiten

-

Magnetische Zylindersensoren

164 Seiten

-

Näherungssensoren

315 Seiten

-

Presence Detection

170 Seiten

-

Industrial Safety Systems

1038 Seiten

-

Identification solutions

300 Seiten

-

Fluidsensorik

243 Seiten

-

Encoder

483 Seiten

-

Distanzsensoren

404 Seiten

-

Mess- und Detektionslösungen

108 Seiten

-

Zone control

5 Seiten

-

Lichtleiter-Sensoren

6 Seiten

-

Induktive Näherungssensoren

5 Seiten

-

T-Easic® FTS

12 Seiten

-

FLOWSIC100 PROCESS

134 Seiten

-

SPEETEC 1D

6 Seiten

-

AHS/AHM36 SSI Inox

29 Seiten

-

STEEL INDUSTRY

8 Seiten

-

MultiPulse

37 Seiten

-

WTB16 Bluetooth®

135 Seiten

-

LFV 310/330

48 Seiten

-

WT18X-3P930

2 Seiten

-

FLG Standard automation light grids

12 Seiten

-

Advanced Automation Light Grids

92 Seiten

-

QAL3 Master

4 Seiten

-

MCS100FT FTIR Analysis System

12 Seiten

-

GM960 Boiler Wall Monitor

8 Seiten

-

Dust measuring devices

171 Seiten

-

Maritime Emissions Monitoring

2 Seiten

-

Raw Gas Measurement

2 Seiten

-

TranspaTect product information

16 Seiten

-

PACKAGING2009/10

20 Seiten

Archivierte Kataloge

-

MCS300P Souverän an der Spitze

4 Seiten

-

MKAS Modulare Analysensysteme

2 Seiten

-

FLOWSIC100

4 Seiten

-

GM32 In-situ-Gasanalysator

8 Seiten

-

safety laser scanners

5 Seiten

-

3D cameras

6 Seiten

-

Miniature photoelectric sensors

5 Seiten

-

W9-2 Small photoelectric sensors

7 Seiten

-

Product overview Industrial Sensors

100 Seiten

-

News Factory Automation

8 Seiten