Katalogauszüge

AP™ Bearings for Industrial Applications

Katalog auf Seite 1 öffnen

index a b c d e Introduction Development and Advantages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Bearing Reconditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Description of Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Basic Bearing Assembly Dimensions and Ratings. . . . . . . . . . . . . . . . . 9 Overall Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 How to Identify Assembly Numbers and Part Numbers Bearing...

Katalog auf Seite 2 öffnen

A T RO DU CT IO N A IN a IntrODuction Development and Advantages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Bearing Reconditioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Description of Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Basic Bearing Assembly Dimensions and Ratings. . . . . . . . . . 9 Overall Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Katalog auf Seite 3 öffnen

When Timken introduced its revolutionary AP™ (Ail-Purpose) rail- road bearings in 1954, it was a railroad industry milestone. Decades later, Timken is a leader in the friction management and power transmission industries and continues to lead in advancing bear- ing technology through continuous innovation and development. In addition to railroad applications, AP bearings are successfully used in many types of industrial applications. This can be attrib- uted to many factors including the bearing's high load carrying ca- pacity and its adaptability to a wide variety of applications....

Katalog auf Seite 5 öffnen

TIMKEN® AP BEARING ASSEMBLY • The narrow adapter shown in Fig. 1 can be used in many ap- plications. Another type of mounting utilizes a full bore housing (see page 21 ). While this type of housing is currently unavail- able through Timken, most bearing distributors provide a selec- tion from other manufactuerers. • The bearing assembly is pressed on the axle as a completely sealed unit. The axle end cap, cap screws and locking plate can be applied to the axle as a unit. When the axle end cap, as shown in Fig. 1 is used, the locking plate provided locks the cap The recessed end cap, not...

Katalog auf Seite 6 öffnen

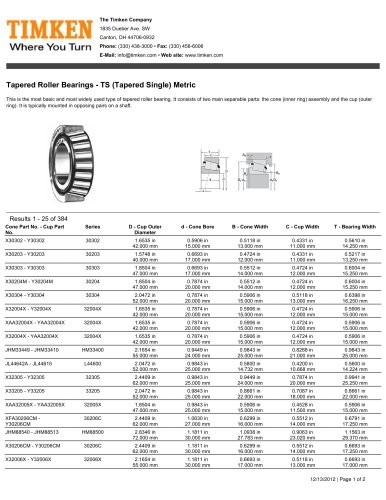

Basic Bearing Assembly Dimensions and Ratings 1,1 Cone bore tolerance + 0.025 -0.000 mm (+ .0010 In. - .0000 In.) ,4> K Factor Is defined as the tapered roller bearing radial to axial dynamic capacity ratio. NOTE: Special cup O.D. tolerance +0.102 + 0.076 mm (+ .0040 In. + .0030 In.) also available. AP™ BEARINGS FOR INDUSTRIAL APPLICATIONS 9

Katalog auf Seite 7 öffnen

Shroud Shroud Recessed End Axle End Cap Basic Bearing Backing Ring111 Backing111 Cap Assembly Assembly Assembly Assemblies Spacer 11 Backing ring assemblies and/or backing spacer may be used on either side of the bearing. Overall Dimensions for AP Bearings ,2> On Classes B, C, and D the lubricant fitting extends beyond the axle end cap. Dimensions given include the lubricant fitting. 10 AP™ BEARINGS FOR INDUSTRIAL APPLICATIONS

Katalog auf Seite 8 öffnen

As s B em yN bl um bers B How to Identify Assembly Numbers and Part Numbers Bearing Assembly Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Standard Part Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 an dP ar t Nu rs B if y be e nt m H o w t o Id

Katalog auf Seite 9 öffnen

HOWTO IDENTIFY ASSEMBLY NUMBERS AND PART NUMBERS HOW TO IDENTIFY ASSEMBLY NUMBERS BEARING ASSEMBLY NUMBERS In order to facilitate the identity of groups of parts, a "bearing as- sembly number" system is used. AP bearings are each assigned a five digit numeric code that follows the cone part number to describe the individual component parts, prelubrication, perfor- mance codes, and internal clearance of the pre-set assembly. In some cases the code maybe alphanumeric, although the first digit For new applications, an assembly number is assigned on receipt of the first order. It is very...

Katalog auf Seite 11 öffnen

HOW TO IDENTIFY ASSEMBLY NUMBERS AND PART NUMBERS STANDARD PART NUMBERS Standard Parts for Timken AP Bearings Pipe Plug Lock Plate- Seal Wear Ring- Pipe Plug Cup Cone Spacer Cone & Roller Pipe Plug - Basic Bearing With Without Shroud Shroud Backing Ring 14 AP™ BEARINGS FOR INDUSTRIAL APPLICATIONS

Katalog auf Seite 12 öffnen

M NT IN GD ESI GNS C OU c mOUNTING dESIGNS Typical Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Crane Bridge and Trolley Axles. . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Moveable Stadium Roof. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 Table Rolls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Continuous Casting Machine Guide Rollers . . . . . . . . . . . . . . . 22 Elevator Sheaves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23...

Katalog auf Seite 13 öffnen

MOUNTING DESIGNS MOUNTING DESIGNS TYPICAL APPLICATIONS Listed below are some of the various applications on which AP bearings are presently being used. Photographs and/or line drawings of some of these designs are shown on the following pages. Apron Feeders • Auto Shredders • Band Saws • Barking Drums-Thrust Billet Ejectors • Bucket Unloaders • Calender Rolls - Billet Grinder Cars Cable Cars Cane Cars Coke Guide Cars Coke Quench Cars Coke Screening Cars Furnace Cars - Furnace Heat Shield Cars - Ingot Cars Ingot Transfer Cars Ladle Transfer Cars Larry Cars Loop Cars Manipulator Cars Orienter...

Katalog auf Seite 15 öffnen

MOUNTING DESIGNS Crane Bridge and Trolley Axle This illustrates a typical AP bearing mounting for crane bridge and trolley axle using recessed end cap. This clamped wheel design is shown on a drive axle. The idler axle design is similar except both bearings are clamped in the same manner as the left-hand assembly shown in Fig. 3. C Fig. 3 Cross section of AP bearing on a drive axle Fig. 4a Fig. 4b Typical full bore housing designs for crane wheel applications 18 APTM BEARINGS FOR INDUSTRIAL APPLICATIONS

Katalog auf Seite 16 öffnenAlle Kataloge und technischen Broschüren von TIMKEN

-

Katalog für Nutzfahrzeuge

417 Seiten

-

Timken Katalog für Kegelrollenlager

706 Seiten

-

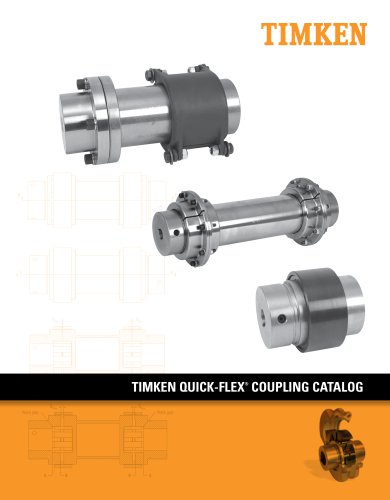

Timken QuiCk-FleX® Coupling CaTalog

68 Seiten

-

TIMKEN® SPHERICAL ROLLER BEARING CATALOG

236 Seiten

-

Timken® Spherical Plain Bearings

6 Seiten

-

National® Industrial Seals

716 Seiten

-

TIMKEN® ECOTURN® SEAL

2 Seiten

-

Timken® Lubricants

6 Seiten

-

Quick-Flex Couplings

68 Seiten

-

Matched Bearing Assemblies

16 Seiten

-

Cylindrical Roller Bearings

108 Seiten

-

AP Bearings

84 Seiten

-

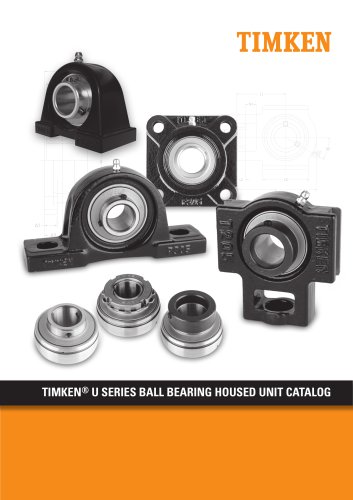

UC Series Ball Housed Units

24 Seiten

-

Type E Housed Units

40 Seiten

-

Ball Housed Units

180 Seiten

-

SNT Plummer Blocks

120 Seiten

-

SAF Housed Units

126 Seiten

-

Thrust Bearings

138 Seiten

-

Quick-Flex Coupling Catalog

68 Seiten

-

Bearing interchange guide

163 Seiten

-

UC-SERIES

24 Seiten

-

Quick-Flex Coupling

64 Seiten

-

Timken Drives Roller Chain Catalog

112 Seiten

-

Industrial Maintenance Manual

157 Seiten

-

Timken SAF Housed Unit Catalog

126 Seiten

-

Timken Type E Housed Unit Catalog

40 Seiten

-

Timken Ball Housed Unit Catalog

180 Seiten

-

Timken® SNT Plummer Block Catalog

120 Seiten

-

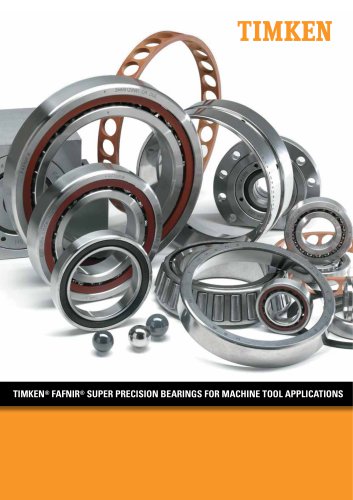

BALL BEARINGS

214 Seiten

-

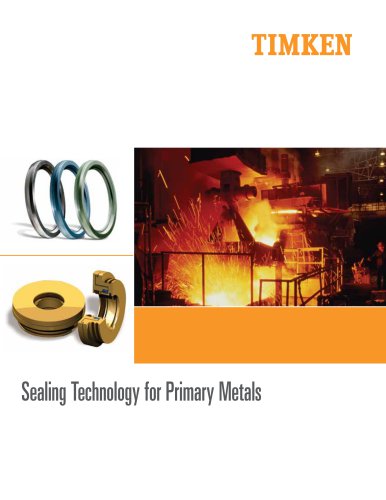

Large Bore Industrial Seal Catalog

40 Seiten

Archivierte Kataloge

-

COMPETENCYBASED TRAINING

5 Seiten

-

Spherical Roller Bearings

236 Seiten

-

Timken Engineering Manual

210 Seiten

-

Timken Ball Bearings Catalog

217 Seiten

-

Timken Industrial Seals

40 Seiten

-

Ball Bearings

6 Seiten

-

IsoClass Bearings

8 Seiten

-

Maintenance Tools

16 Seiten

-

Industrial Products

56 Seiten

-

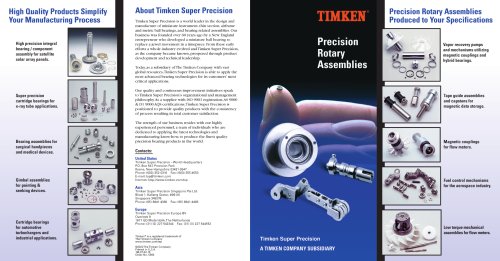

Precision Rotary Assemblies

2 Seiten

-

Ceramic Bearings

2 Seiten